A gas pressure loader refers to fully and semi-automatic firearms that utilize the gas pressure generated by the ignition and combustion of the propellant charge to perform the reloading process. They stand in contrast to recoil loaders. In recoil loaders, the recoil energy is used to accelerate the bolt backward and open it at the end position, which causes the ejection of the empty cartridge from the chamber in the final position. The gas pressure escapes through the muzzle and the opened bolt, after which the bolt is accelerated forward again by a spring. When closing, a new cartridge is introduced into the chamber, and the weapon is ready to fire again.

In gas pressure loaders, however, a portion of the propellant gas is diverted to cycle the bolt, which occurs through a port in the barrel wall. The energy of this diverted gas pressure is used to unlock and open the bolt of the rifle. An advantage of gas pressure loaders is that the locking of the bolt can be maintained securely and structurally simply until the gas pressure in the barrel falls below a critical value, as the gases activate the self-loading mechanism only after the projectile has passed the gas port. Due to the inertia of the mechanism, the bolt is unlocked with a sufficient delay.

The self-loading mechanism is activated by the gas pressure until the projectile leaves the barrel. This time span is referred to in English as "Dwell Time".

Gas pressure loaders are preferred for firing powerful ammunition.

In contrast to recoil loaders, the disadvantages are the increased weight and the larger space requirement for gas pistons and gas rods. Additionally, the system can easily become dirty.

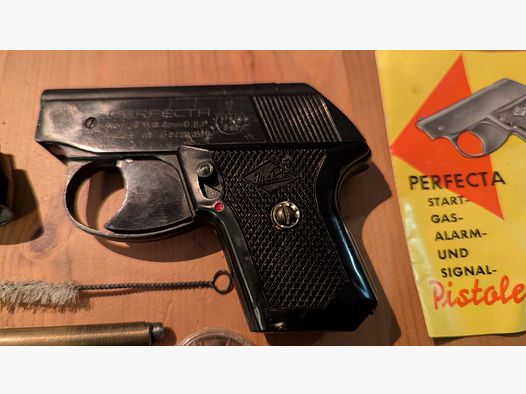

In hunting, gas pressure loaders do not play a significant role.