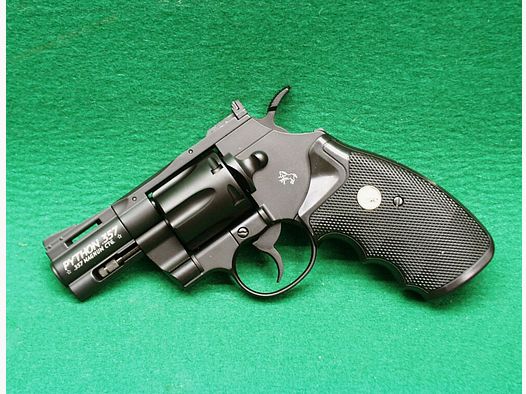

In der Welt der Jagdwaffen sind "Züge" und "Felder" Begriffe, die oft verwendet werden, um die Beschaffenheit von Gewehrläufen zu beschreiben. Diese beiden Elemente spielen eine entscheidende Rolle für die Präzision und Leistung einer Waffe. Züge sind dabei erhabene spiralförmige Rillen entlang der Innenwand des Laufs, während Felder die ungerillten Bereiche zwischen den Zügen sind. Züge dienen dazu, dem Projektil eine Rotation zu verleihen, was die Genauigkeit und Präzision erhöht, während Felder das Geschoss unterstützen, zentrieren und die Abdichtung des Laufs verbessern.

Die Qualität der Züge und Felder eines Gewehrlaufs kann einen erheblichen Einfluss auf die Leistung der Waffe haben. Gut gefertigte Züge und Felder sorgen für eine gleichmäßige Rotation des Geschosses, was zu einer verbesserten Genauigkeit und Präzision führt. Eine stabile Flugbahn des Projektils ist entscheidend, um das Ziel genau zu treffen, insbesondere bei der Jagd auf weite Entfernungen.

Eine effektive Rotation des Geschosses durch die Züge ermöglicht zudem eine größere Reichweite. Jäger können Ziele in größerer Entfernung präzise treffen, wenn ihre Waffe über hochwertige Züge und Felder verfügt. Gute Züge und Felder sorgen auch für eine konsistente Leistung der Waffe, unabhängig von den äußeren Bedingungen. Eine gleichmäßige Rotation des Geschosses ist entscheidend, um die Konsistenz von Schüssen zu gewährleisten, was besonders wichtig ist, wenn es um die Jagd auf verschiedene Arten von Wildtieren geht.

Züge und Felder beeinflussen auch die Wartungsanforderungen der Waffe. Gut gefertigte Züge und Felder sind weniger anfällig für Verschleiß und Ablagerungen, was die Lebensdauer der Waffe verlängern kann. Eine regelmäßige Reinigung und Pflege ist dennoch wichtig, um die Leistung der Züge und Felder aufrechtzuerhalten.

Insgesamt sind Züge und Felder entscheidende Komponenten einer Jagdwaffe, die einen direkten Einfluss auf deren Leistung haben. Jäger sollten sich der Bedeutung von Zügen und Feldern bewusst sein und sicherstellen, dass ihre Waffe über hochwertige und gut gepflegte Laufeigenschaften verfügt. Durch die Auswahl von Waffen mit erstklassigen Zügen und Feldern können Jäger ihre Erfolgsquote verbessern und ein effektiveres und präziseres Jagderlebnis genießen.