Your hunting gear must be reliable – for safety and success. Here you will learn how to identify weaknesses early and keep your equipment in top condition. The key steps at a glance:

- Visual Inspection: Look for rust, cracks, and wear.

- Load Tests: Simulate weather and terrain conditions.

- Functionality Check: Test mechanics and electronics.

- Regular Maintenance: Clean and service your gear.

With these tips, your equipment will remain safe, durable, and ready for use. Read on to understand each step in detail.

Step 1: Visual Inspection

The visual inspection is the first and most important step to identify potential problems early.

Checking for Surface Damage

Proceed systematically during the surface inspection:

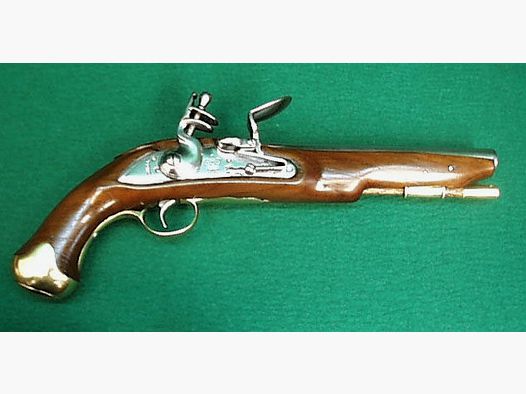

- Rust Formation: Examine metal parts such as barrels, magazines, and bolts for signs of corrosion.

- Material Fatigue: Pay special attention to joints for fine cracks.

- Signs of Wear: Check moving parts for wear.

Ensure adequate lighting and use a magnifying glass to make small details visible. This inspection is especially important after hunts in wet weather or after prolonged storage.

Typical Weaknesses

In addition to surface damage, you should also keep an eye on the typical weaknesses of your hunting gear:

| Equipment Part | Weaknesses | What to Watch For |

|---|---|---|

| Firearms | Bolts, barrels, magazines | Wear, corrosion, functionality |

| Optics | Seals, mounts | Fogging, waterproofing, secure fit |

| Straps & Belts | Seams, buckles | Fraying, cracks, stability of connections |

| Backpacks | Straps, zippers | Wear at edges, functionality of closures |

Particular attention should be paid to:

- Joints: Check all screw connections for a secure fit.

- Seals: Inspect rubber seals for cracks or hardening.

- Joints: Ensure that moving parts operate smoothly.

- Mounts: Check the stability of mounts and brackets.

Safety-related components should be inspected thoroughly. If you have doubts about reliability, early replacement is advisable. On Gunfinder.de, you will find a wide selection of spare parts and accessories from well-known manufacturers.

Once the visible defects are noted, you can proceed with mechanical load and functionality tests.

Step 2: Load Tests

Weather and Terrain Tests

Your gear must withstand various weather and terrain influences under real hunting conditions. Here are some tests you can perform:

Water Resistance:

- Simulate light rain to test the resilience of your gear.

- Conduct a controlled immersion test to ensure that waterproof gear remains truly watertight.

- Check optics for fogging by exposing them to temperature changes.

Soil and Mud Tests:

- Place your gear in damp soil or sand to assess dirt resistance.

- Check seals and closures for functionality after contact with dirt.

- Thoroughly clean the equipment and check for dirt accumulation in critical areas.

In addition to these tests, you should also check the mechanical load-bearing capacity of your gear under pressure conditions.

Load and Pressure Tests

After the gear has withstood the weather and terrain tests, it is time to test its structural load-bearing capacity. These tests help identify material limits. Always pay attention to the manufacturer's specifications regarding maximum loads. Here are some approaches:

- Straps and Belts: Gradually increase the tensile load without exceeding material limits.

- Backpacks: Load them slowly to test the load-bearing capacity of seams and connections.

- Optical Mounts: Test stability under sudden changes in load.

- Clothing: Simulate typical movements with full gear to assess load-bearing capacity under realistic conditions.

Important Notes for Load Tests:

- Start with moderate loads and gradually increase them.

- Pay special attention to joints between different materials.

- Listen for unusual noises and observe visible deformations.

- Document any irregularities to compare the condition of the equipment over time.

Be cautious during these tests, as excessive loading can jeopardize warranty claims. If you are unsure, have your gear checked by a professional. You can find spare parts and accessories for repairs on Gunfinder.de.

sbb-itb-1cfd233

Step 3: Function Tests

After you have tested your gear under real conditions, it is time to check its functionality in detail.

Systematic Function Checks

Proceed systematically and check each component to ensure that both mechanics and electronics work smoothly.

Firearms and Bolts:

- Test the bolt under various temperature conditions.

- Check the magazine feed with different types of ammunition.

- Inspect the function of the firing pin and trigger.

Optical Systems:

- Ensure that the adjustment mechanisms work evenly.

- Test image quality under various lighting conditions.

- Check the parallax adjustment for precision.

Equipment Accessories: Check closures, buckles, and folding mechanisms for stability and ease of use. Also, pay attention to the functionality of safety mechanisms.

Don't forget to test the equipment under extreme weather conditions to ensure its reliability.

Tests in Extreme Weather

The operational capability of your gear in extreme weather conditions is crucial. Here is an overview of the most important temperature tests:

| Temperature Range | Test Duration | Aspects to Check |

|---|---|---|

| -15°C to -5°C | 2 hours | Mechanical function, material brittleness |

| 0°C to 10°C | 3 hours | Fogging, tightness |

| 20°C to 35°C | 4 hours | Heat resistance, material expansion |

Cold Tests:

- Store the equipment for at least 2 hours at -10°C.

- Check if moving parts function even in the cold.

- Test if the equipment remains fog-free during temperature changes.

Moisture Tests:

- Expose the equipment to controlled light rain.

- Check electronic components for functionality in high humidity.

- Inspect seals and closures for waterproofing.

Tip: Ideally, conduct these tests 2–3 weeks before your hunt. This allows enough time for any necessary repairs or adjustments.

Step 4: Regular Maintenance

To ensure your gear remains reliably functional over time, regular maintenance is essential. After the load and function tests, consistent care will keep your equipment in excellent condition and prevent it from letting you down.

Cleaning and Storage

After each hunt, you should thoroughly clean your gear. Remove dirt and moisture to protect firearms, optics, and clothing from damage. Pay special attention to sensitive parts that can wear quickly. Proper dry and secure storage is also important to avoid unnecessary wear.

Creating a Maintenance Plan

A fixed maintenance plan helps you keep track. Schedule regular inspections and cleanings to identify wear early. This way, you can make necessary repairs or replace parts in a timely manner and ensure that your equipment is always ready for use.

Finding Spare Parts

If you need spare parts or accessories, Gunfinder.de offers a convenient solution. There, you will find a wide selection of accessories and spare parts from trusted dealers – ideal for keeping your gear in top shape long-term.

Conclusion

The tests make it clear: Regular inspections and load tests ensure reliable hunting gear and extend its lifespan.

Important Check Steps

A systematic review of hunting gear helps identify weaknesses early. Document the results to notice wear in time and take targeted action.

Benefits of Regular Maintenance

Through regular testing and care, repair costs can be reduced and the reliability of the equipment increased. You can find high-quality spare parts at Gunfinder (https://gunfinder.de) to keep your gear in top condition.

Well-maintained equipment is not only a matter of safety but also of successful hunting.