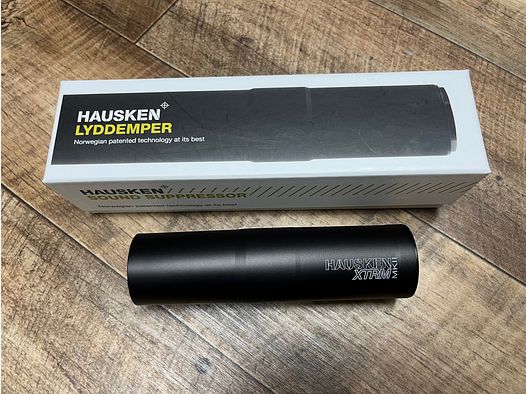

The use of suppressors in hunting has significantly increased in recent years. They offer a number of advantages, including a reduction in muzzle flash, recoil, and noise. However, like all components of a firearm, suppressors require proper care and maintenance to ensure their longevity and functionality. In this article, we will take an in-depth look at suppressor maintenance.

Basics of Suppressor Maintenance

Suppressors are robustly constructed and typically do not require excessive maintenance. Nevertheless, over time, condensation, powder residues, and dirt can accumulate inside the suppressor. These deposits can impair the efficiency of the suppressor and lead to corrosion. Therefore, it is important to clean and inspect the suppressor regularly.

Cleaning the Suppressor

Disassembly

Before cleaning the suppressor, it must be removed from the firearm. Ensure that the firearm is unloaded and secured before beginning disassembly.

Dry Cleaning

First, the suppressor should be freed from coarse dirt using a brush or cloth. For hard-to-reach areas, special cleaning tools such as nylon brushes or cleaning wires can be used.

Wet Cleaning

After dry cleaning, the suppressor can be treated with a suitable cleaning agent. There are special solvents available that dissolve dirt and powder residues. Ensure that the cleaning agent is suitable for suppressors and does not attack the materials.

Drying

After wet cleaning, the suppressor must be thoroughly dried. This can be done either in the air or with a cloth. Ensure that no moisture remains inside the suppressor, as this can lead to corrosion.

Inspection

After cleaning, the suppressor should be checked for damage or signs of wear. This includes scratches, dents, cracks, or corrosion. If you notice such signs, the suppressor should be inspected by a professional.

Reassembly

After cleaning and inspection, the suppressor can be reattached to the firearm. Ensure that it is securely and correctly fastened.

Lubrication and Care

Suppressors should be regularly treated with a suitable lubricant to protect them from corrosion and extend their lifespan. Here are some steps to consider when lubricating and maintaining suppressors:

Choose a high-quality lubricant specifically designed for firearms and suppressors. It should be able to withstand high temperatures and pressure and provide excellent corrosion protection.

Apply the lubricant to all exterior and interior surfaces of the suppressor. Ensure that all parts, including threads and seals, receive a thin layer of lubricant. Use a clean cloth or brush to distribute the lubricant evenly.

Allow the lubricant to penetrate the surface for a few minutes. Then wipe off any excess lubricant.

Depending on usage and conditions, this process should be repeated regularly. A good rule of thumb is to lubricate and maintain the suppressor after each use or at least once a month.

Storage of the Suppressor

Proper storage of the suppressor can significantly extend its lifespan. When not in use, the suppressor should be stored in a dry and cool place. It should not be stored in a damp or salty environment, as this can lead to corrosion.

Additionally, it is advisable to store the suppressor in a protective bag or case to protect it from dust and dirt. Before storing the suppressor, ensure that it is clean, dry, and well-lubricated.

Summary

The maintenance and care of suppressors is an essential task for every hunter or shooter. A well-maintained suppressor not only offers better performance but also lasts longer. Through regular cleaning, lubrication, and inspection, problems can be detected and resolved early. Proper storage further protects the suppressor from damage and corrosion.